Planetary reduction motors are widely used in various industrial and automation equipment due to their unique design and superior performance. They have many significant advantages.

First, planetary reduction motors are compact and can provide high torque output in a limited space. This makes them very suitable for space-constrained application scenarios such as robot joints and small automation equipment.

Secondly, planetary reduction motors have a wide range of reduction ratios and can usually achieve higher reduction ratios, which means they can effectively reduce speed while increasing output torque. This feature makes planetary reduction motors perform well in applications that require high torque and low speed, such as conveyors, elevators, and power tools.

In addition, planetary gear motors generally have small backlash, enabling high-precision control and positioning. This is especially important for applications that require precise motion control, such as CNC machine tools and automated assembly lines.

Finally, the durability and reliability of planetary gear motors also make them ideal for industrial applications. Because they are made of high-strength metal materials, they can withstand large loads and harsh working environments, extending the service life of the equipment and reducing maintenance costs.

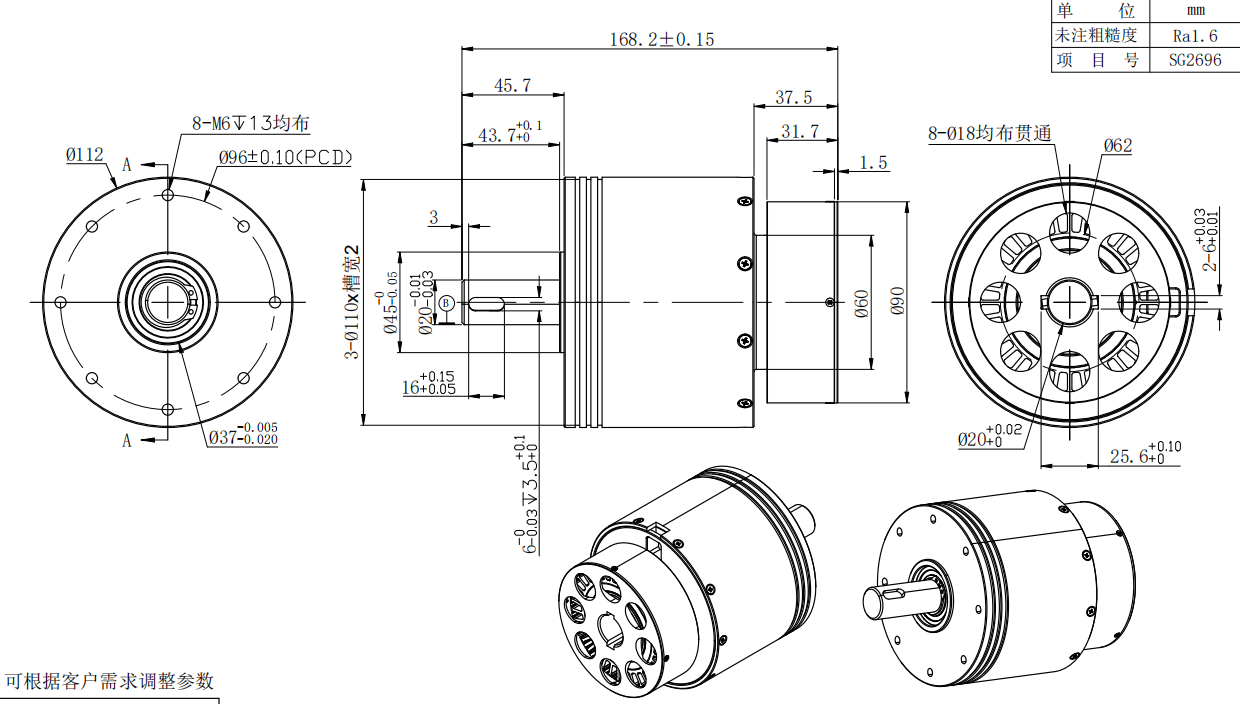

|

Housing material

|

Steel |

| Outer diameter | 112 mm |

| Reduction ratio | 30.25 |

| Voltage | 24 V |

| Rated Speed | 30 RPM |

| Rated Current | <10 A |

| Rated Torque | 45 Nm |

| Peak Torque | 135 Nm |