The cycloidal gear motor is ideal for many industrial applications due to their unique design and superior performance.

First of all, cycloidal gear motors have the advantage of high torque output. Its cycloidal gear structure can effectively convert the rotational motion of the motor into powerful torque, making it suitable for applications requiring high loads, such as heavy machinery and automation equipment. This high torque characteristic allows the motor to still provide strong power at lower speeds, ensuring stable operation of the equipment.

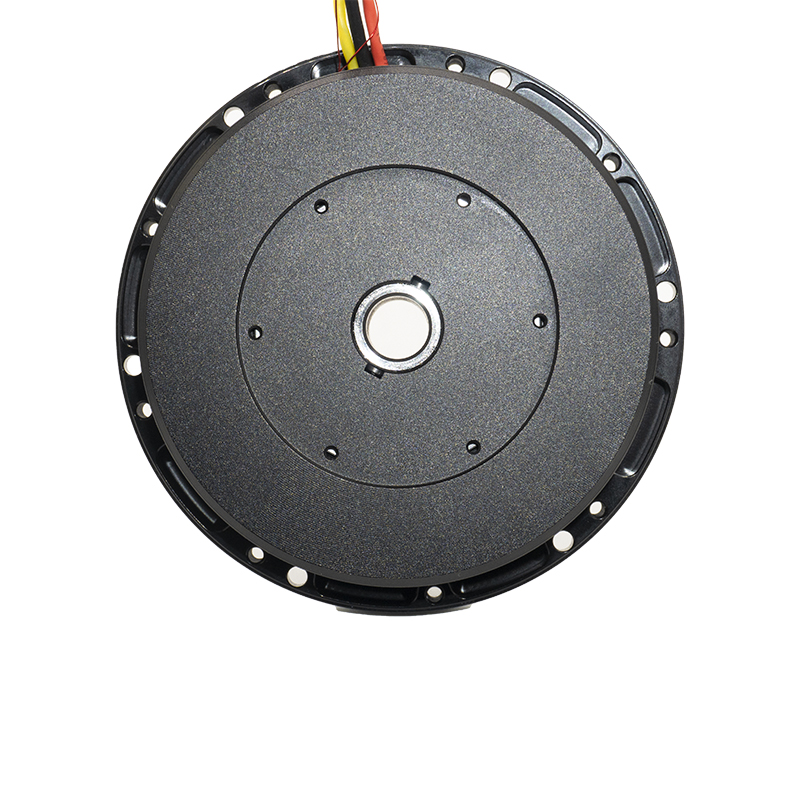

Secondly, the cycloidal gear motor has a compact structure and can achieve efficient power transmission in a limited space. Compared with traditional gear motors, the design of cycloidal gear motors is flatter, lowering the center of gravity and improving overall stability. This compact design makes it easy to install in small working environments and meets the high requirements for space utilization in modern industry.

In addition, the durability and reliability of cycloidal gear motors are also outstanding. The use of high-strength materials and precision processing technology allows it to maintain excellent performance under long-term operation and high load conditions, reducing maintenance frequency and costs. The low noise and low vibration characteristics of the motor also provide users with a more comfortable working environment.

| Material | Steel |

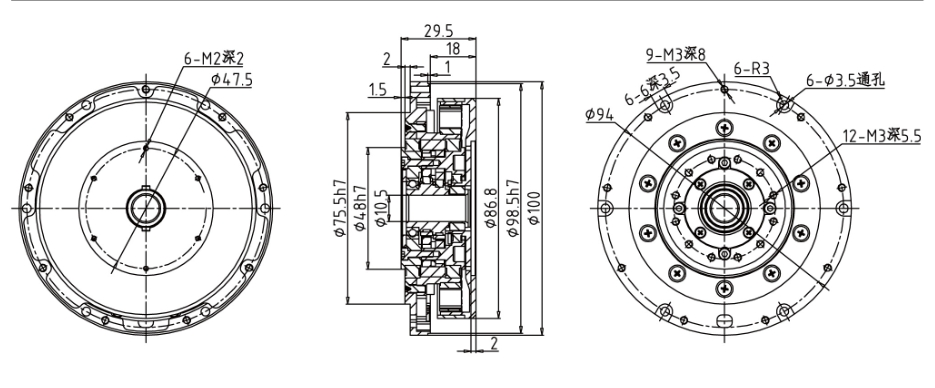

| Outer diameter | 100mm |

| Thickness | 29.5mm |

| Backlash | 5-10arcmin |

| Transmission structure | Cycloidal |

| Reduction ratio | 25 |

| Voltage | 24-48V |

| Rated power | 500W |

| Rated speed | 60RPM |

| No-load speed | 90RPM |

| Rated torque | 25NM |

| Peak torque | 75NM |

|

Thermistor

|

10KB3435%1 |

|

Motor KV value

|

63kv |

| Phase inductance | 290uH |

|

Phase current full scale

|

33A |

| Rated bus current | 15A |

| Static working bus | 0.08A |

| Motor structure | 21 Antipodes |

| Weight | 822g |

| Reaction potential constant | 0.143V/rad |