Recently, SigGear successfully R&D a new type of cycloidal gear motor--SG-2556, which can provide dual magnetic encoders. This product has significantly improved in both precision and performance, making it particularly suitable for high-precision applications such as exoskeletons and robotic arms. The newly developed gear motor not only boasts high efficiency but is also equipped with a dual magnetic encoder drive board, further enhancing its capabilities in precision positioning.

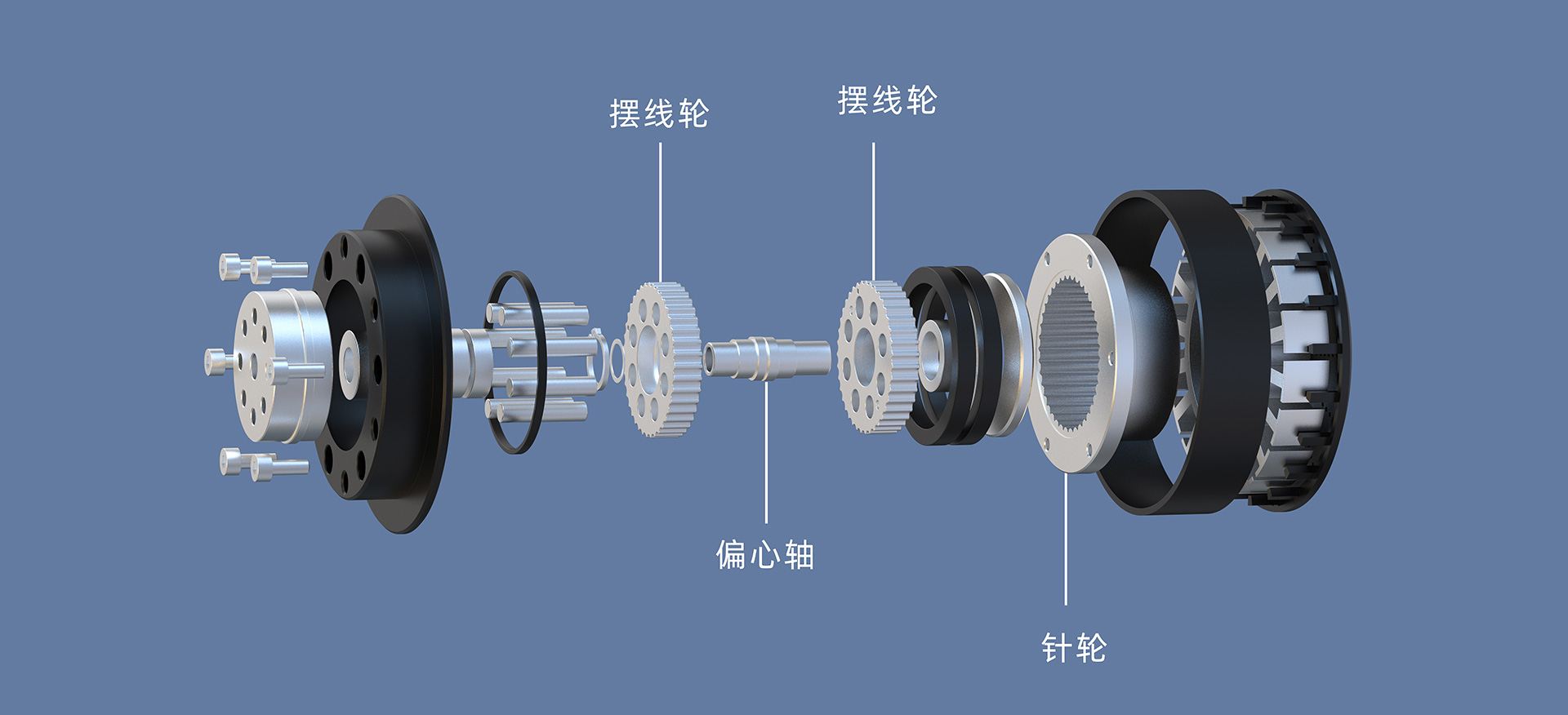

The cycloidal gear motor has gained widespread application in industrial automation and robotics in recent years due to its unique structural design and superior transmission characteristics. The SG-2556 incorporates multiple technological innovations based on traditional cycloidal gear motors, particularly in backlash control, successfully reducing backlash to less than 3 arcmin. This breakthrough allows the motor to achieve higher positioning accuracy during precision operations, meeting modern industrial demands for high precision and efficiency.

The core advantage of the SG-2556 lies in its application of the dual magnetic encoder drive board. This board, through high-precision encoders and advanced control algorithms, can monitor the motor’s rotational state in real-time, ensuring stability and reliability during operation. The introduction of this technology not only enhances the motor’s response speed but also significantly reduces errors caused by backlash, allowing the motor to perform exceptionally well in complex tasks.

In applications involving exoskeletons and robotic arms, precision positioning is key to achieving efficient operations. The SG-2556 cycloidal gear motor, with its outstanding performance, can provide more flexible motion control for exoskeletons, assisting users in executing complex movements in various environments. Additionally, in robotic arm applications, the motor’s high precision enables robots to perform more delicate operations in assembly, welding, handling, and other industrial scenarios, thereby improving production efficiency and product quality.

Moreover, the design of this motor fully considers heat dissipation and durability, utilizing advanced materials and processes to ensure that it maintains good performance even under prolonged high-load operation. This characteristic gives the new cycloidal gear motor a longer service life and lower maintenance costs in industrial production.

With the continuous development of smart manufacturing and automation technologies, the demand for high-precision motors is increasing. The SG-2556 cycloidal gear motor, with its exceptional performance and broad application prospects, is expected to become an important driving force in the future of industrial automation.

Post time: Jan-20-2025