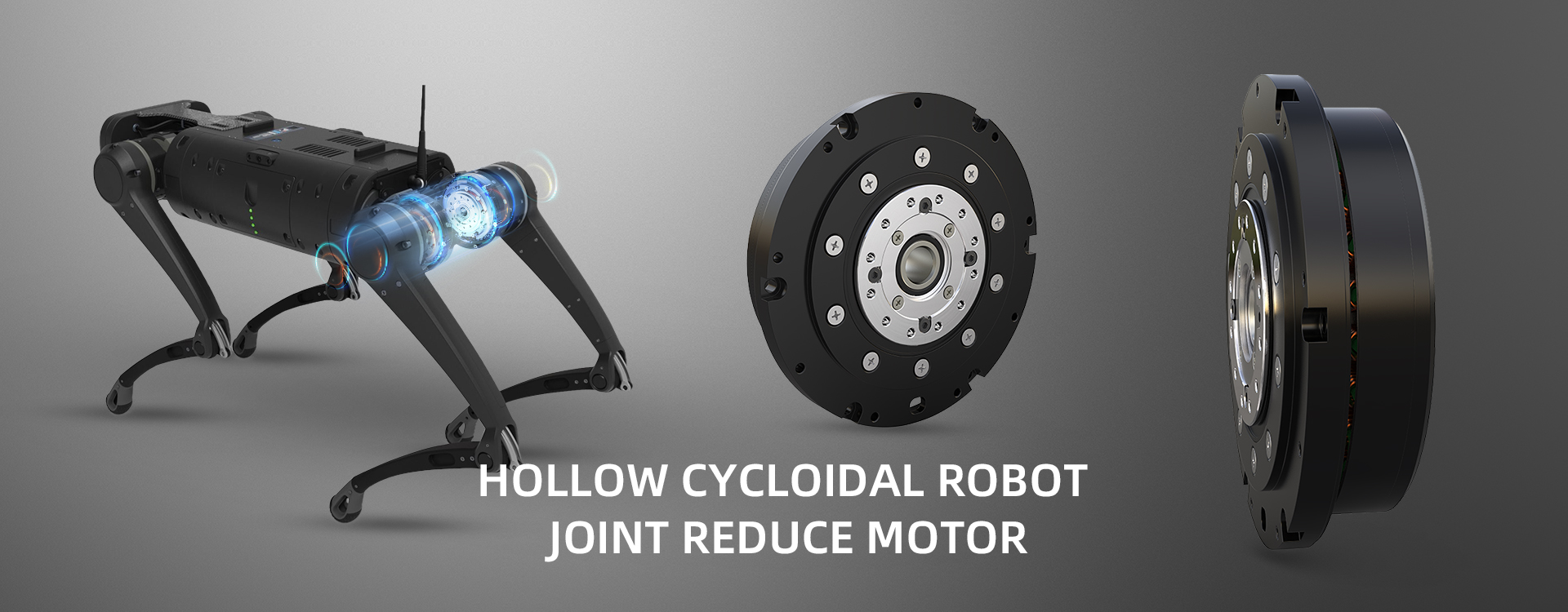

With the rapid development of modern industrial technology, joint reduction motors, as key components of automation equipment, have become the focus of industry attention regarding performance optimization and efficiency enhancement. In this context, the cycloidal structure stands out in the field of joint reduction motors due to its unique advantages, becoming an important force in driving technological innovation.

The core advantages of the cycloidal structure in joint reduction motors are mainly reflected in the following aspects:

High Transmission Efficiency

The transmission efficiency of the cycloidal structure is significantly higher than that of traditional gear transmissions. Its unique tooth profile design allows for tighter meshing, reducing energy loss and achieving higher transmission efficiency. This is undoubtedly a huge advantage for joint reduction motors that require stable operation over long periods.

High Precision Positioning

Another notable feature of the cycloidal structure is its excellent positioning accuracy. The continuity and uniformity of the cycloidal tooth profile enable the motor to achieve more precise angular displacement control during operation. This is crucial for applications such as precision assembly on automated production lines and robotic operations.

Low Noise and Long Lifespan

Compared to traditional gear structures, the cycloidal structure generates less noise and vibration during operation. This not only enhances the comfort of equipment use but also helps extend the lifespan of the motor. Additionally, the wear resistance and impact resistance of the cycloidal structure are stronger, further ensuring the long-term stable operation of the motor.

Compact Design

The compact design of the cycloidal structure allows for a greater transmission ratio within limited space. This is particularly significant for applications in space-constrained environments, such as aerospace and medical devices. By adopting the cycloidal structure, motor performance can be improved without increasing volume.

In practical applications, cycloidal structure joint reduction motors have been widely used in various fields. For example, in the industrial robotics sector, cycloidal reduction motors ensure precise operation of robots with their high accuracy and stability; in automated production lines, the high transmission efficiency and low noise characteristics of cycloidal reduction motors enhance production efficiency and product quality. Furthermore, in logistics handling and precision machining, cycloidal reduction motors play an irreplaceable role.

In summary, the core advantages and application prospects of the cycloidal structure in joint reduction motors are evident. With continuous technological advancements and growing market demand, it is believed that the cycloidal structure will be widely applied in more fields in the future, injecting new vitality into the development of industrial automation.

Therefore, we look forward to more enterprises and research institutions exploring the potential of the cycloidal structure in depth, jointly promoting the innovation and development of joint reduction motor technology, and contributing more wisdom and strength to modern industrial manufacturing.

Post time: Nov-26-2024