|

Housing Material :

|

Steel

|

Gear Material:

|

steel

|

|

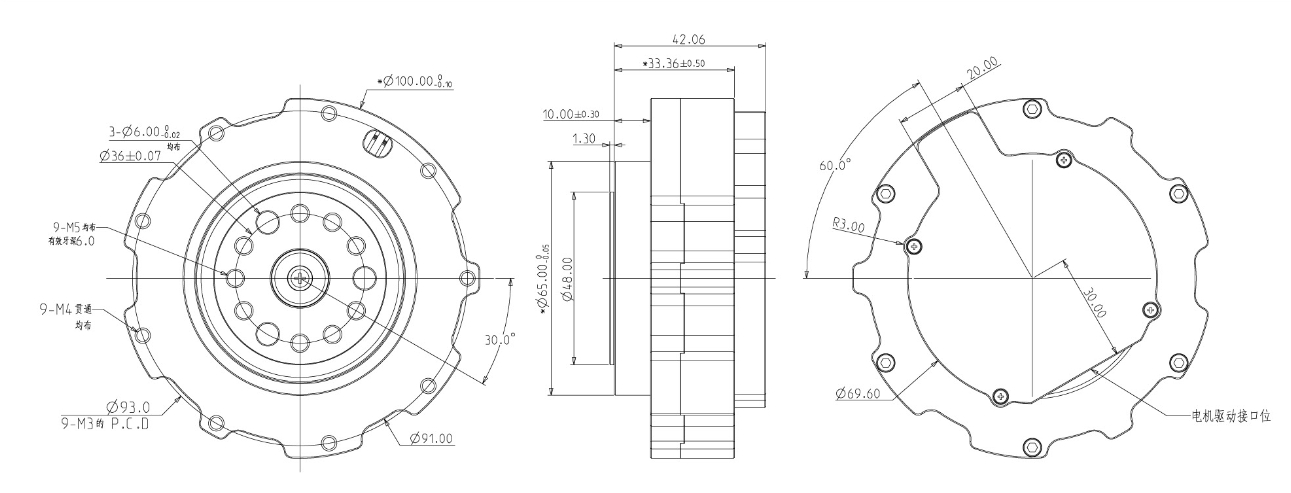

Outer Diameter:

|

100MM

|

Length ( thickness):

|

42.6mm

|

|

Reduce Ratio:

|

9.25:1

|

Backlash:

|

15-20 arcmin

|

|

Number of poles :

|

21 |

Weight:

|

305g

|

|

Motor Power:

|

500W

|

Motor KV value:

|

63kv |

|

thermister:

|

10K B3435 %1

|

NTC B value :

|

3435

|

|

Output Rated Speed:

|

160RPM

|

Output Un-load Speed:

|

240RPM

|

|

Output Rated Torque:

|

10Nm

|

Voltage :

|

DC 24V-48V

|

|

Output Peak Torque :

|

30Nm

|

Phase Damping :

|

224

|

|

Rated bus bar current :

|

12A

|

Phase current full scale:

|

33A

|

SG-8021 is an efficient planetary gearbox reduction device widely used in mechanical transmission systems. This product's structure is flat, which the BLDC is integrated with planetary gearbox. Because of its unique structure and working principle, making it perform well in many fields. The planetary gearbox motor is composed of several key components, including sun gear, planet gear, ring gear, planet carrier and the BLDC motor. The sun gear is located in the center, the planet gears rotate around it and are connected through the planet carrier, and the ring gear is the external fixed gear.

The working principle of a planetary gearbox is relatively simple. When the sun gear is driven, the planet gears rotate around it while meshing with the ring gear. Because the number of planetary gears is usually larger, they can evenly share the load, thereby improving transmission efficiency and load-bearing capacity. This design makes the planetary gearbox relatively small in size and weight, but can provide a large reduction ratio and high torque output.

The advantages of planetary gearboxes are not only reflected in their efficient transmission performance, but also in their good stability and durability. Due to the distributed load characteristics of planetary gears, the gearbox generates less wear during operation and has a longer service life. In addition, the planetary gearbox has a compact structure and can achieve efficient power transmission in a limited space. It is suitable for various industrial equipment, robots, aerospace, automotive and other fields.

In practical applications, planetary gearboxes can be configured and designed differently according to needs to meet specific working conditions and performance requirements. With the advancement of technology, the materials and manufacturing processes of planetary gearboxes are also constantly improving, allowing them to operate stably under extreme conditions such as high loads, high speeds, and high temperatures.