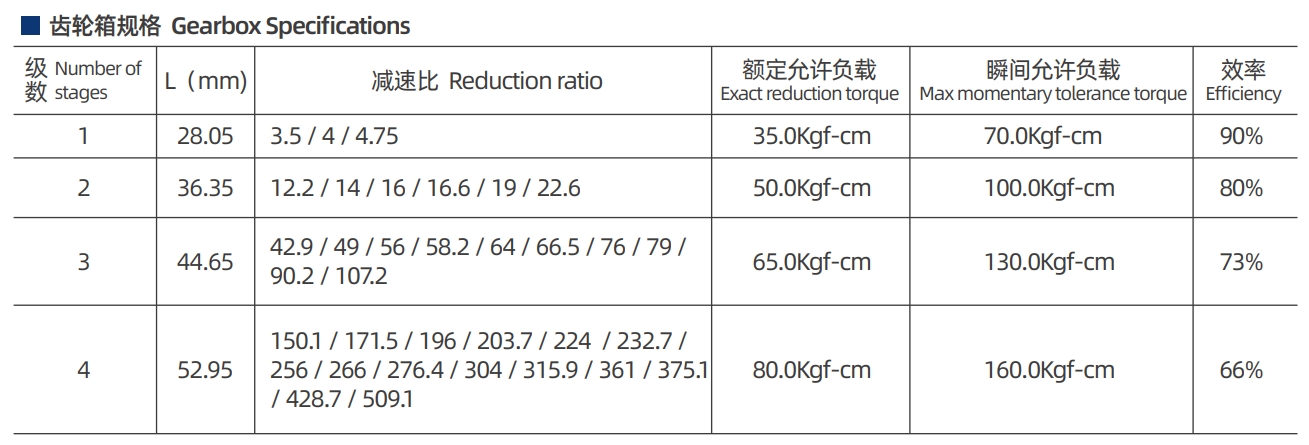

| No.of stages | 1~10PCS | 10~50PCS | 50~200PCS | 200~500PCS | ≥500PCS |

| 1 | 90USD | 80USD | 65USD | 50USD | Negotiatio |

| 2 | 100USD | 85USD | 70USD | 55USD | Negotiatio |

| 3 | 105USD | 90USD | 80USD | 65USD | Negotiatio |

| 4 | 115USD | 100USD | 85USD | 70USD | Negotiatio |

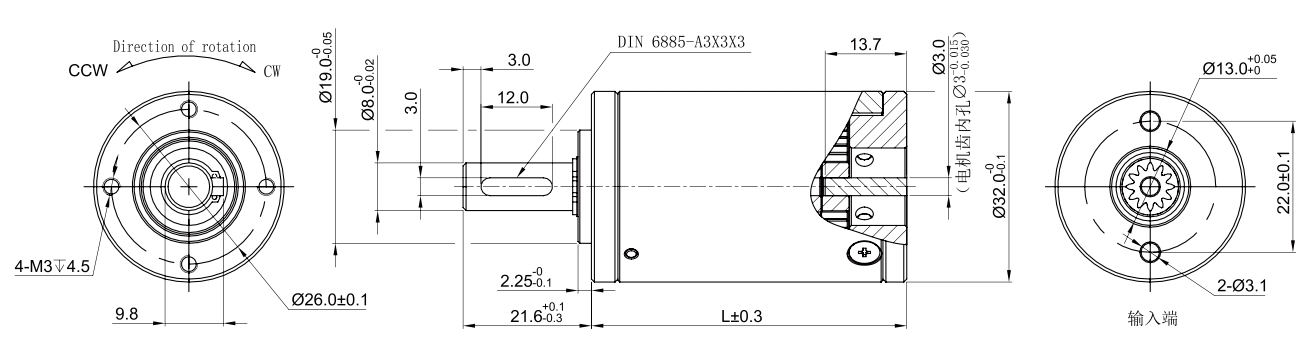

| Outer Diameter: | 32mm | Product of Origin: | Guangdong ,China |

| Brand: | SigGear /OEM / ODM | Motor Type: | Brush ,Brushless , Coreless .Stepper.etc |

| Protect Level: | Basic ,Totally Enclosed , Water proof or customized request | Application Field: | Customer Request |

| Life Time Warranty: | At least 2 years | Structure: | Spur Gearbox , Planetary , Worm , Cycloidal, Harmonic |

| Material: | Metal and Plastic | Certification: | ISO9001 ITAF16949 |

Advantages of planetary reducer:

1. High torque density. The planetary reducer is composed of several gears such as sun gear, planet gear and ring gear meshing with each other, and the torque load can be distributed to different gears. Therefore, under the same volume, the planetary reducer can withstand higher torque than other reducers.

2. Save costs. With the planetary reducer, the designer can use a smaller power motor, because the power is smaller, the cost of the overall configuration has to be greatly reduced.

3. High precision. Up to an arc minute.

4. Low noise. Operating noise can reach a minimum of 55 decibels.

5. Be efficient. Planetary gear train efficiency loss is small, so the transmission efficiency of up to 97%.

6. High deceleration ratio. Through the combination of multiple stages or multiple stages, a variety of different and higher deceleration ratios can be assembled.

7. Wide range of applications. Due to the high torque density, high precision, high reduction ratio and compact characteristics of planetary reducer, there are unlimited potential uses in industrial applications.

| Housing material | Steel |

| Gearwheel material | Steel |

| Bearing at output | Ball Bearings |

| Radial load(10mm from flange) | ≤8.0kgf |

| Shaft axial load | ≤3.5kgf |

| Radial play of shaft | ≤0.04mm |

| Thrust play of shaft | ≤0.3mm |

| Backlash,at no-load | ≤1.2° |

| Max permissible speed at continuous working | ≤8000RPM |

| Operating temperature range | -40~120℃ |

| Nominal(VDC) | 3 ~ 36VDC |

| DC motors | Suitable for DC motors with power less than 100W,When the motor cannot meet the installationrequirements of the reducer,it needs to be negotiated separately. |

Note: Only part of the data is presented in the table. If there is any need, please communicate with the project leader to accept the design and development of special specifications.