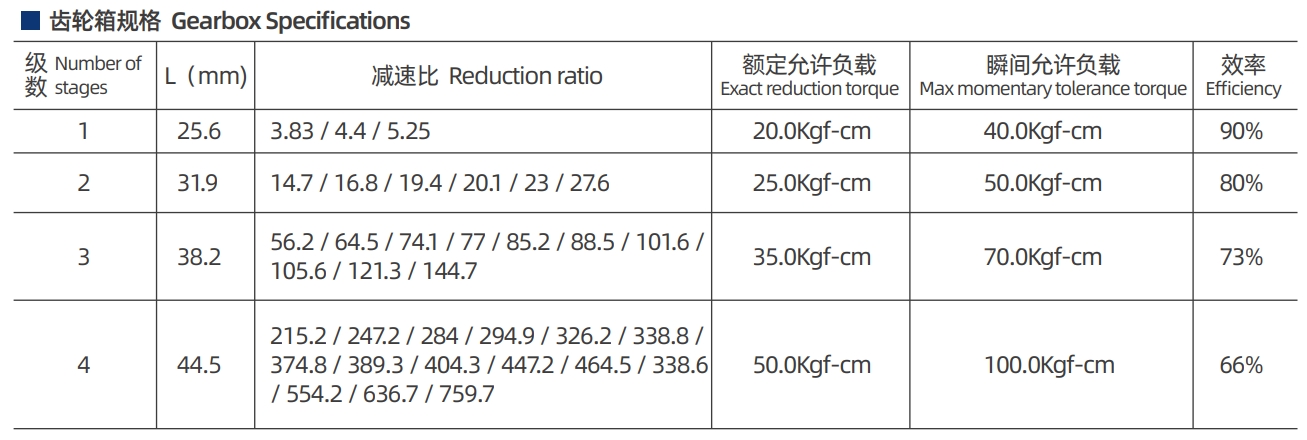

| NO.of stages | 1~10PCS | 10~50PCS | 50~200PCS | 200~500PCS | ≥500PCS |

| 1 | 90USD | 80USD | 65USD | 50USD | Negotiation |

| 2 | 100USD | 85USD | 70USD | 55USD | Negotiation |

| 3 | 105USD | 90USD | 80USD | 65USD | Negotiation |

| 4 | 115USD | 100USD | 85USD | 70USD | Negotiation |

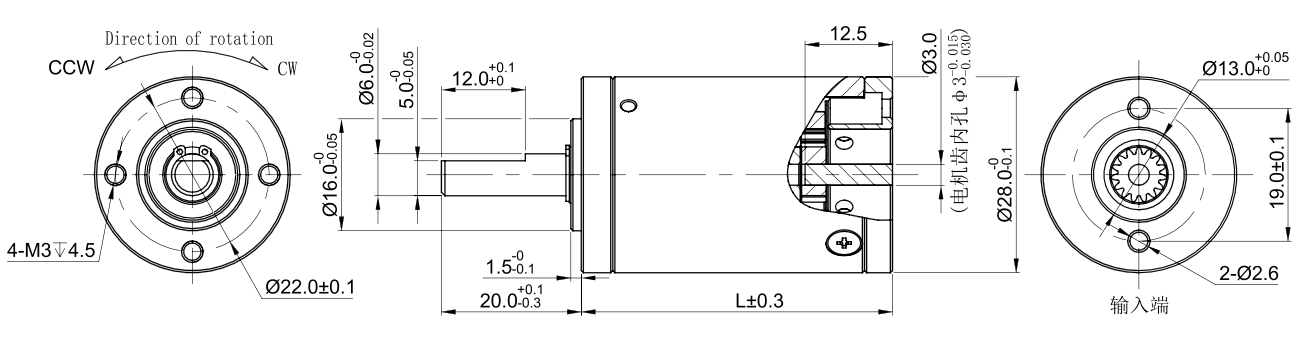

| Outer Diameter: | 28mm | Product of Origin: | Guangdong ,China |

| Brand: | SigGear /OEM / ODM | Motor Type: | Brush ,Brushless , Coreless .Stepper.etc |

| Protect Level: | Basic ,Totally Enclosed , Water proof or customized request | Application Field: | Customer Request |

| Life Time Warranty: | At least 2 years | Structure: | Spur Gearbox , Planetary , Worm , Cycloidal, Harmonic |

| Material: | Metal and Plastic | Certification: | ISO9001 ITAF16949 |

Planetary gear motor is a common reducer motor, its main advantages are as follows:

1. High efficiency: planetary gear motor because of its internal gear transmission mode design, in the transmission torque using multiple support points, relative to other gear motors more torque characteristics, in the transmission of mechanical output power, can effectively reduce the transmission loss, improve mechanical efficiency.

2. Compact structure: Due to the reasonable design of its internal structural components, the planetary gear motor is small in size, and its shell is compact and beautiful. They can often be used in applications with limited space, thus increasing the available space.

3. Lower noise and vibration: The gears of planetary gear motors are in a more stable position and generally have lower noise and vibration levels than other types of gear systems.

| Housing material | Steel |

| Gearwheel material | Steel |

| Bearing at output | Ball bearings |

| Radial load(10mm from flange) | ≤6.0kgf |

| Shaft axial load | ≤3.0kgf |

| Radial play of shaft | ≤0.04mm |

| Thrust play of shaft | ≤0.3mm |

| Backlash,at no-load | ≤1.2° |

| Max permissible speed at continuous working | ≤8000RPM |

| Operating temperature range | -40~120℃ |

| Nominal(VDC) | 3 ~ 36VDC |

| DC motors | Suitable for DC motors with power less than 30W,When the motor cannot meet the installationrequirements of the reducer,it needs to be negotiated separately. |

Note: Only part of the data is presented in the table. If there is any need, please communicate with the project leader to accept the design and development of special specifications.