22MM DC 12V 24V planetary gear motor reducer motor

The 22mm 12V-24V planetary gear motor is an efficient power transmission device designed for compact applications and is widely used in robots, automation equipment, small machinery and other fields. Its small size and powerful performance make it an indispensable power solution in modern industry.

This planetary gear motor uses a high-precision planetary gear transmission system to provide excellent torque output in a limited space. Regardless of the voltage selection of 12V or 24V, the motor can achieve smooth operation and efficient energy conversion to meet the needs of different application scenarios. Its flat design not only lowers the center of gravity and improves stability, but also effectively reduces vibration and noise, ensuring quiet operation of the equipment.

In addition, the durability and reliability of the 22mm planetary gear motor are also fully guaranteed. The use of high-strength materials and advanced manufacturing processes enables it to maintain excellent performance under high loads and long-term operation. The high torque characteristics of the motor enable it to easily cope with various complex working environments and improve the overall efficiency of the equipment.

| NO.of stages | 1~10PCS | 10~50PCS | 50~200PCS | 200~500PCS | ≥500PCS |

| 1 | 100USD | 85USD | 70USD | 55USD | Negotiation |

| 2 | 105USD | 90USD | 80USD | 65USD | Negotiation |

| 3 | 115USD | 100USD | 85USD | 70USD | Negotiation |

| 4 | 120USD | 105USD | 90USD | 80USD | Negotiation |

| Outer Diameter: | 28mm | Product of Origin: | Guangdong ,China |

| Brand: | SigGear /OEM / ODM | Motor Type: | Brush ,Brushless , Coreless .Stepper.etc |

| Protect Level: | Basic ,Totally Enclosed , Water proof or customized request | Application Field: | Customer Request |

| Life Time Warranty: | At least 2 years | Structure: | Spur Gearbox , Planetary , Worm , Cycloidal, Harmonic |

| Material: | Metal and Plastic | Certification: | ISO9001 ITAF16949 |

Product Description

In the gear motor series products, the planetary gear reducer with its small size, high transmission efficiency, wide deceleration range, high precision and many advantages, and is widely used in servo, stepping, DC and other transmission systems. Its role is to ensure the premise of precision transmission, mainly used to reduce the speed and increase the torque and reduce the load/motor moment of inertia ratio. The reducer has the advantages of small volume, light weight, high bearing capacity, long service life, stable operation and low noise. It has the characteristics of power shunt and multi-tooth meshing. Applicable to lifting and transportation, construction machinery, metallurgy, mining, petrochemical, construction machinery, light industry textile, medical instruments, instruments, automobiles, ships, weapons and aerospace and other industrial sectors

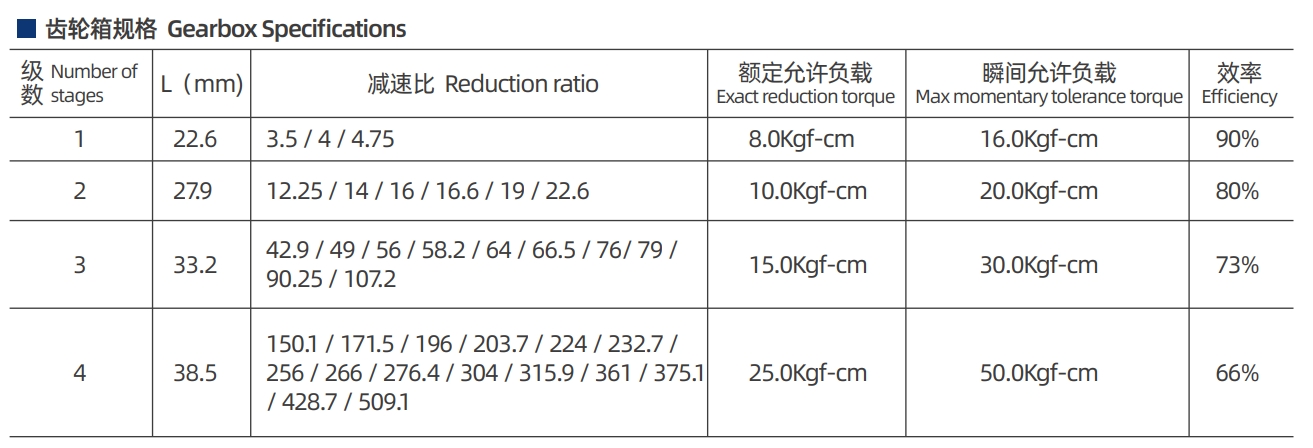

Gearbox Specification

| Housing material | Steel |

| Gearwheel material | Steel |

| Bearing at output | Ball Bearings |

| Radial load(10mm from flange) | ≤1.6kgf |

| Shaft axial load | ≤0.5kgf |

| Radial play of shaft | ≤0.04mm |

| Thrust play of shaft | ≤0.2mm |

| Backlash,at no-load | ≤1.5° |

| Max permissible speed at continuous working | ≤8000RPM |

| Operating temperature range | -40~120℃ |

| Nominal(VDC) | 3 ~ 36VDC |

| DC motors | Suitable for DC motors with power less than 25W,When the motor cannot meet the installationrequirements of the reducer,it needs to be negotiated separately. |

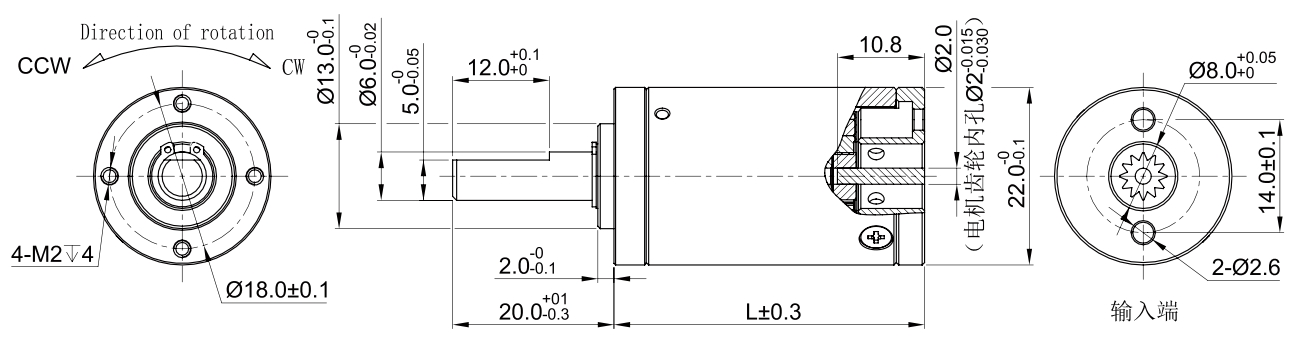

Technical ilustration

Technical Parameter

Note: Only part of the data is presented in the table. If there is any need, please communicate with the project leader to accept the design and development of special specifications.

WHY CHOOES OUR PRODUCTS

-

Quality Assurance

Different needs to provide different design, committed to providing high-end precision transmission system solutions

-

Production base

More than 13000 square meters. 11 assembly lines ,Stable and efficient, sufficient supply

-

Advanced equipment

Equipment imported from Switzerland, Germany and Japan. High-precision production and inspection

-

CUSTOM ON DEMAND

Strictly design and produce by our customer's detail parameter requirement.

INDUSTRY APPLICATION PART DISPLAY

RELATED PRODUCTS

-

-

24MM planetary gear motor DC high ratio large t...

-

SG6010H–500W 18Nm robot joint module use ...

-

SG6010D–500W 50Nm robot joint module use ...

-

20MM planetary gear motor DC 3V 12V 24V low bac...

-

24MM planetary gear motor DC high ratio large t...

-

SG6010H–500W 18Nm robot joint module use ...

-

SG6010D–500W 50Nm robot joint module use ...

-

20MM planetary gear motor DC 3V 12V 24V low bac...

-

24MM planetary gear motor DC high ratio large t...

-

SG6010H–500W 18Nm robot joint module use ...

-

SG6010D–500W 50Nm robot joint module use ...